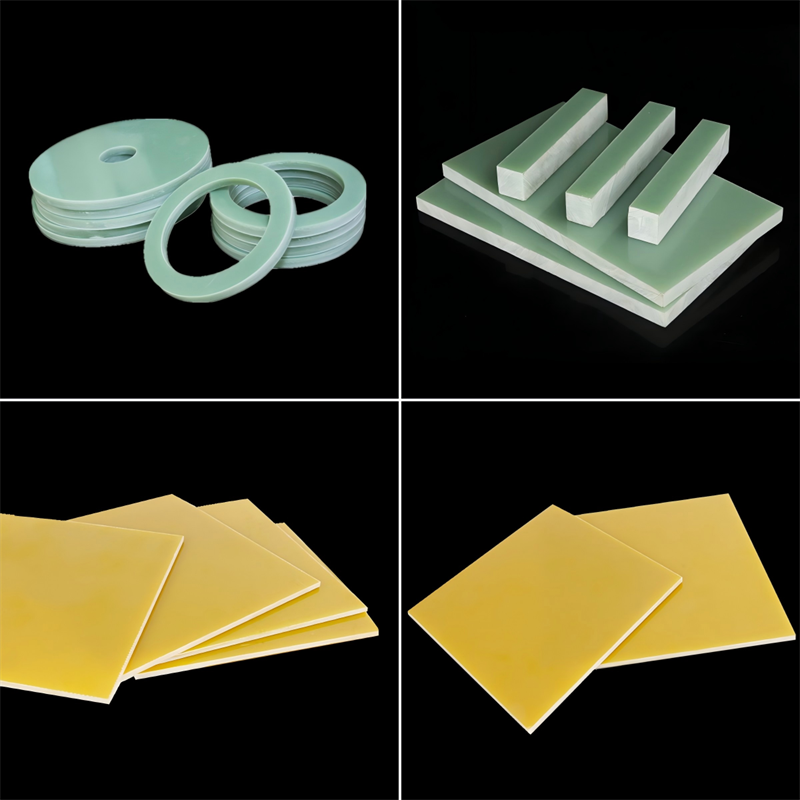

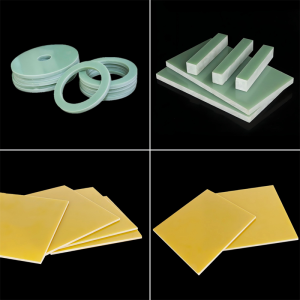

FR4 / 3240 / G10 / G11 – Grade Reference

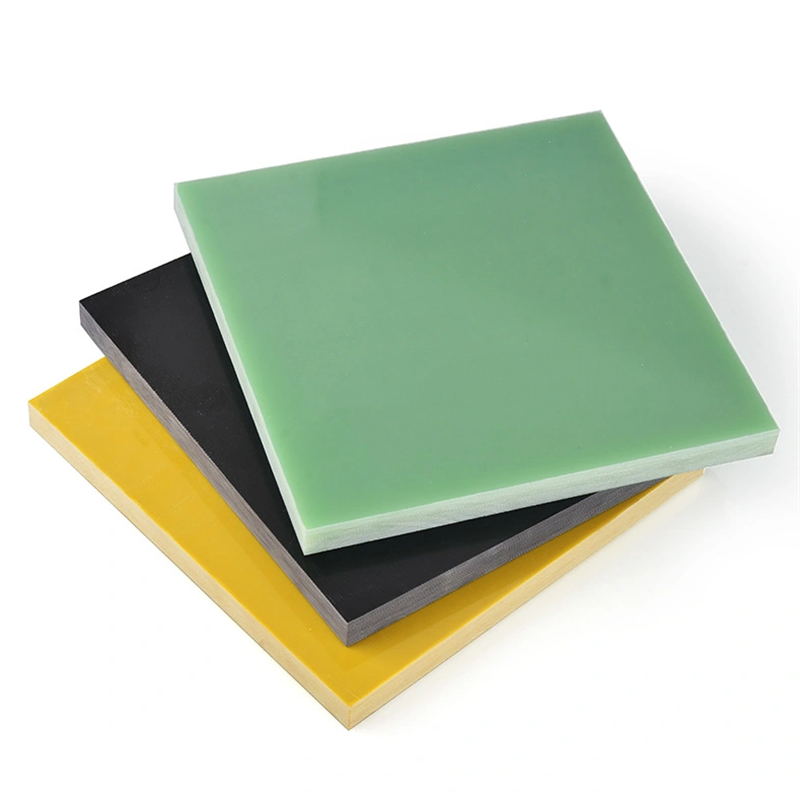

FR4: Flame-retardant epoxy glass laminate widely used in electrical and electronic insulation applications.

3240: Common Chinese standard epoxy glass laminated sheet, similar in structure and performance to FR4.

G10: Non-flame-retardant epoxy glass laminate with comparable mechanical and electrical properties.

G11: High-temperature epoxy glass laminate designed for more demanding thermal environments.

FR4 / 3240 sheets are commonly selected as a practical alternative to G10 and G11 in most industrial insulation applications.

Features & Benefits:

1. Excellent electrical insulation properties

2. High mechanical strength and rigidity

3. Good thermal resistance and dimensional stability

4. Flame-retardant performance (FR4 grade)

5. Low water absorption and good moisture resistance

6. Good resistance to oils, chemicals, and solvents

7. Easy to machine: cutting, drilling, CNC processing

Basic Specifications:

| Chinese Name |

3240 |

3241 |

| IEC |

EPGC201 |

EPGC202 |

EPGC203 |

EPGC204 |

EPGC306 |

EPGC308 |

一 |

| NEMA |

– |

FR4 |

G10 |

FR5 |

G11 |

– |

– |

| Basic Material |

Glass fiber cloth |

ELectronic grade glss fiber cloth |

Glass fiber

cloth |

| Resin |

Epoxy |

Heat-resistant epxoy resin |

Epoxy |

| Color |

Nature/Yellow |

Nature/Green |

Black |

| Test item |

Unit |

Value |

Value |

| Density |

g/m³ |

1.8~1.95 |

1.75~1.90 |

Vertical layer bending

strength (nomal) |

MPa |

≥340 |

≥300 |

Parallel layer impact strength

(simply supported beam

method) |

KJ/m2 |

≥38 |

250 |

Vertical layer electrical

strength

(90℃transformer oil) |

Kv/mm |

≥14.2 |

≥8.0 |

Parallel layer breakdown

voltage(90°℃transformer oil) |

kv |

≥35 |

≥35 |

≥40 |

≥35 |

≥40 |

≥35 |

≥35 |

| Dielectric constant(50Hz) |

|

≤5.5 |

≤5.5 |

| Dielectric loss factor(50Hz) |

– |

≤0.04 |

≤0.03 |

Insuation resistance after

immersion |

Ω |

≥5.0*1010 |

≥1.0*108 |

| Proof tracking index(PTI) |

– |

|

– |

|

|

≥200 |

二 |

– |

| Combustibility |

– |

|

V-0 |

– |

V-0 |

– |

– |

HB40 |

| Temperature index |

一 |

130 |

130 |

155 |

155 |

155 |

180 |

180 |

Water absorption(1-20mm

thickness) |

mg |

17~73 |

64~193 |

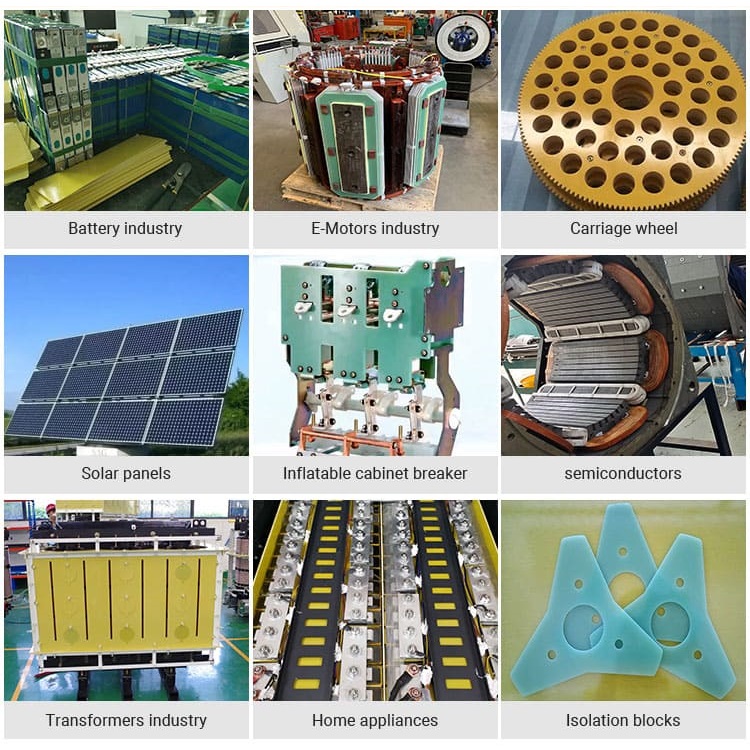

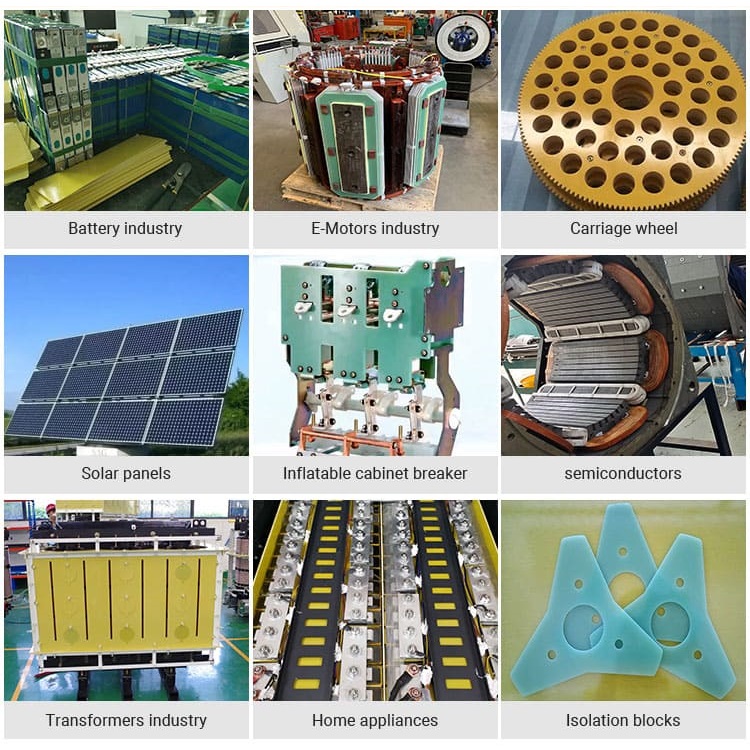

Application:

* Electrical insulation parts for motors and transformers

* Switchgear, circuit breakers, and electrical panels

* Insulating spacers, supports, and structural components

* PCB fixtures, test jigs, and electrical tooling

* Industrial mechanical parts requiring insulation and strength

* Applications where G10 or G11 sheets are traditionally used