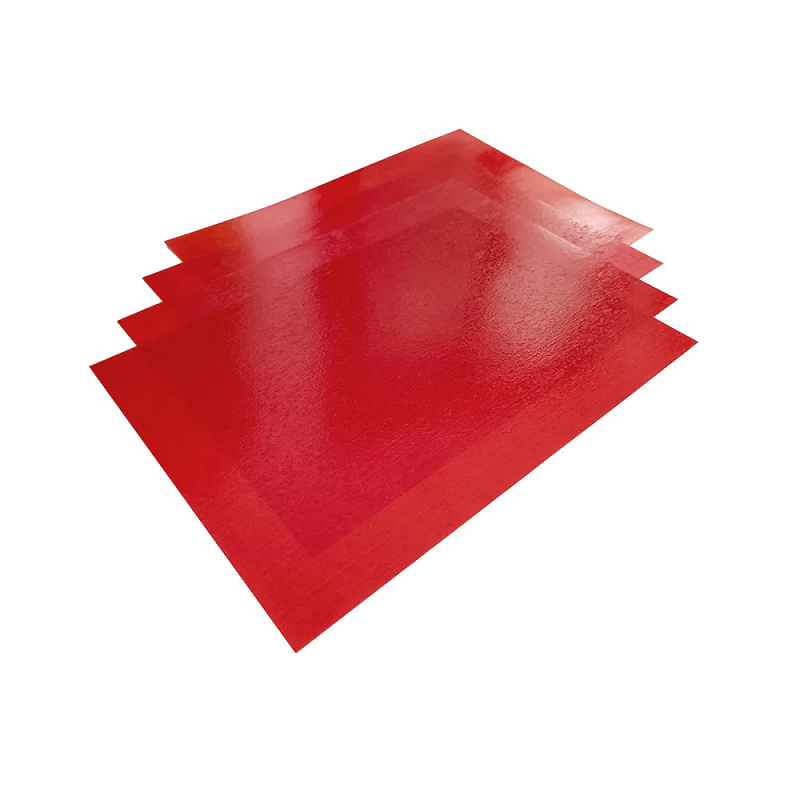

Features & Benefits:

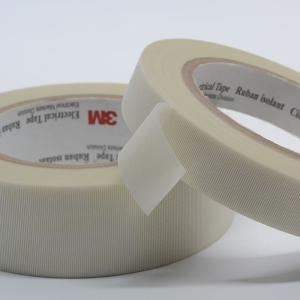

1. High mechanical strength and excellent electrical properties, suitable for high-strength insulation systems.

2. Good flexibility, strong adhesion between the resin and DMD substrate, no powder shedding, and no discoloration.

3. Long storage life and simple forming process.

4. High soluble resin content, ensuring the product tightly bonds with metal conductors after curing, with exceptional peel strength.

5. Low volatile content, ensuring excellent partial discharge performance of the product.

6. Outstanding heat resistance, capable of withstanding high temperatures, suitable for F-grade insulation systems (maximum operating temperature of 155°C)

Basic Specifications:

| Item |

Unit |

Requirement |

| Nominal thickness |

mm |

0.18 |

0.2 |

0.23 |

0.25 |

0.3 |

0.4 |

| Thickness tolerance |

mm |

±0.02 |

±0.03 |

±0.04 |

| Grammage |

g/m2 |

200±20 |

240±28 |

250±37 |

290±45 |

380±53 |

460±54 |

| Tensile strength |

MD no bending |

N/10mm |

≥80 |

≥120 |

| Breakdown voltage |

KV |

≥8 |

≥10 |

| Soluble resin content |

g/m2 |

≥45 |

| Volatile content |

% |

≤1.5 |

| Tensile shear strength |

Mpa |

≥5 |

| Temperature index(TI) |

– |

≥155 |

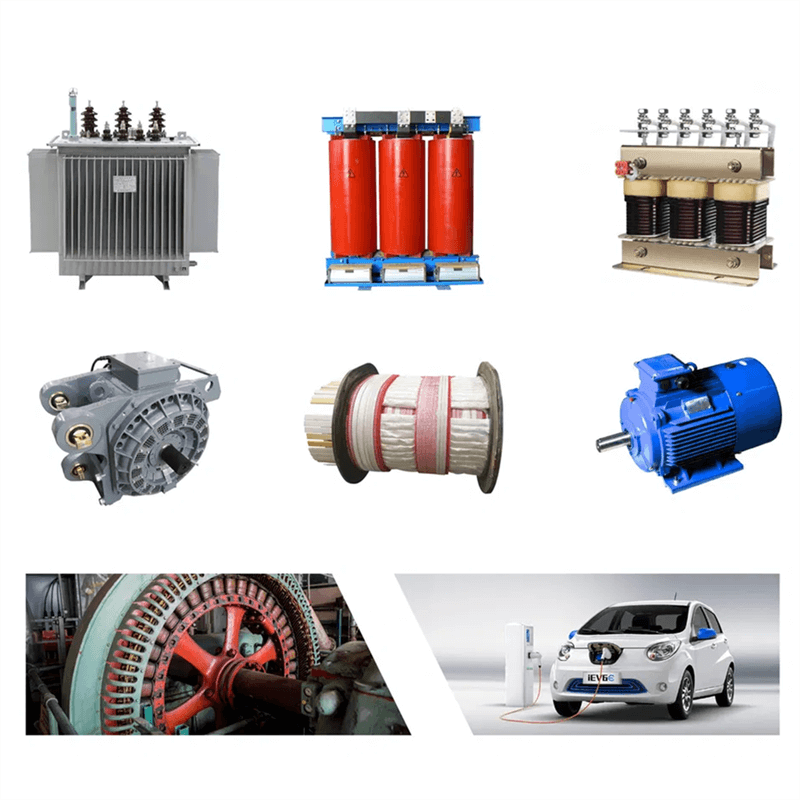

Application:

* Interlayer insulation for low-voltage coils of dry-type transformers: Serves as an interlayer insulation material, effectively isolating coils with different voltage levels, preventing electrical breakdown, and enhancing safety.

* Slot and phase insulation for F-grade motors: Used for slot and phase insulation in motors, improving insulation performance and operational reliability while extending equipment lifespan.

* Insulation for other electrical equipment: Suitable for other electrical equipment requiring high insulation performance, such as capacitors, voltage regulators, and high-voltage devices.

* Base material for wound laminated tubes: Used in the production of wound laminated tubes, providing high mechanical strength and excellent heat resistance, ideal for specialized electrical structural applications.