Kapton Polyimide Film & Tape Series

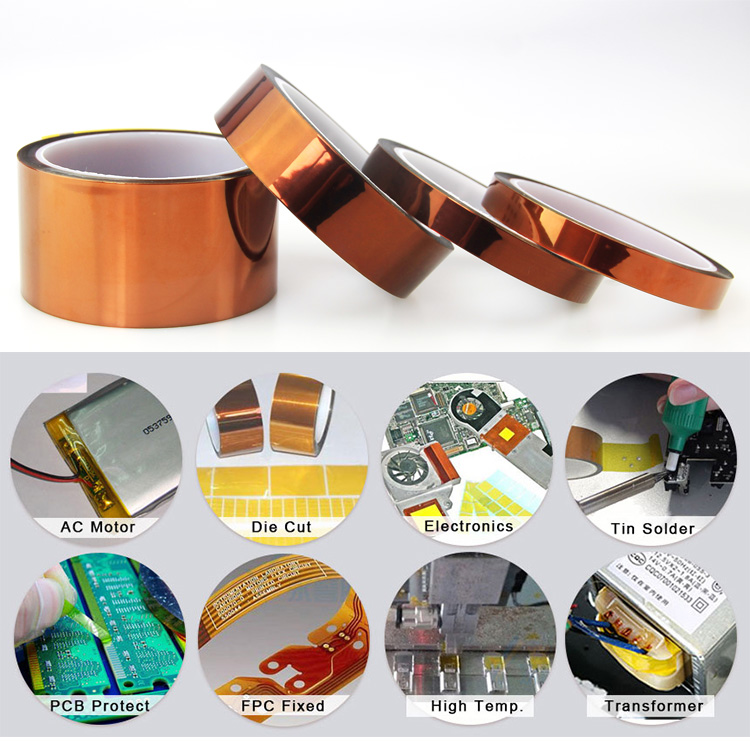

Single Side Kapton Polyimide Tape

GBS Kapton polyimide film tape is a type of high temperature masking tape, especially designed to provide heat resistance masking protection for the application of electronic industry. It uses polyimide film as carrier with one side organic silicone adhesive coated. The regular thickness ranges from 35um-175um, and it features excellent chemical stability, radiation resistance and operating temperature(up to 260℃). Polyimide tape can be used in high temperature working temperature on printed circuit boards during wave solder or reflow soldering, SMT surface mounting, transformer manufacturing, as well as lithium battery positive and negative and ears fixed. It has been widely used in Aerospace, aviation, marine, spacecraft, missile, rockets, atomic energy, electrical and electronic industry and other fields.

Double Side Kapton Polyimide Tape

Double side polyimide kape tape use polyimide film as carrier with double side silicone adhesive coated.The product has mainly been utilized in the gold finger protection during the circuit plate (PCB) over wave crease welding, transformer insulation binding, lithium cell polar ear fixing, and other occasions that need heat-resistance.

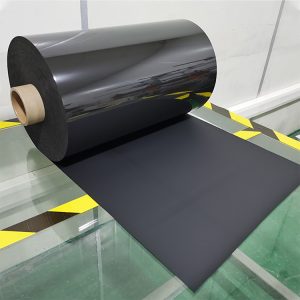

Kapton Polyimide film for H-class Transformer and Motor Insulation

Polyimide film is also well known as Kapton film, especially designed for heat resistant and H-class insulation application such us transformer, motors, cables, lithium battery, etc. It features great radiation resistance, shear resistance, solvent resistance, and high class insulation. Our regular thickness for Polyimide film ranges form 7um to 125um for choice. Besides of that, it’s quite easy to be die cut into different shapes & sizes like round disc, square shapes or other irregular custom shapes according to the customer’s different application.

Features & Benefits:

High performance silicone pressure sensitive adhesive makes it over a high temperature resistance up to 260℃. Featuring good shear resistance and radiation resistance, chemical solvent resistance and anti-corrosion. It’s an excellent material that provides high class electrical insulation. Besides, it’s easy to peel off without residue.

The regular thickness ranges from 35um-175um

Available to die-cut in any custom shape design and size.

Applications:

Benefit with power performance and stable quality, Polyimide film tape can be used in various applications during manufacturing. It can be used to protect the circuit board during wave solder or reflow soldering or used as an electrical insulation components for capacitor and transformer wrapping. It’s also very well known to used in powder coating industry for high temperature masking.

Here at GBS, we have our own coating workshop, which can help customize different adhesive solutions according to customer’s requirement.

Served Industries:

Aerospace industry — as insulation function for aircraft and space craft wings

PCB Board manufacturing — as golden finger protection during wave solder or reflow soldering

Capacitor and transformer — as wrapping and insulation

Powder coating — as high temperature masking

Automotive industry — for wrapping switches, diaphragms, sensors in seat heaters or auto’s navigation part.

Leave Your Message

-

Poron Polyurethanes Foam Material For Electronic Components Cushioning&Gap Filling

Read more -

0.4-3mm Thickness Double Side VHB Foam Tape for Various Industries Mounting

Read more -

3M 1600T Alternative Double Sided PE foam tape for General Purpose Bonding

Read more -

HT-840 Extra Firm Cellular Bisco Silicone Foam for Outdoor Enclosures Sealing&Gasketing

Read more