Features & Benefits:

1. High resistance to extreme temperatures, humidity, and thermal shock.

2. Excellent resistance to ion migration.

3. Superior mechanical properties, suitable for flexible circuit boards, with strong electrical performance.

4. Flame retardant (UL certified) and high heat resistance.

5. Good dimensional stability, high CTE modulus, and low coefficient of thermal expansion.

6. Strong peel strength and excellent die-cutting properties.

7. Excellent chemical resistance and insulation performance.

8. Low resin flow and great filling ability, ideal for both fast and conventional lamination.

9. Strong mechanical properties and low dielectric constant.

10. Outstanding storage stability.

Besic Specifications:

| Property |

Value |

| Type |

GBS-25 |

| Adhesive |

Modified acrylic adhesive |

| Liner |

Release film and paper |

| Carrier |

Non-carrier |

| Color |

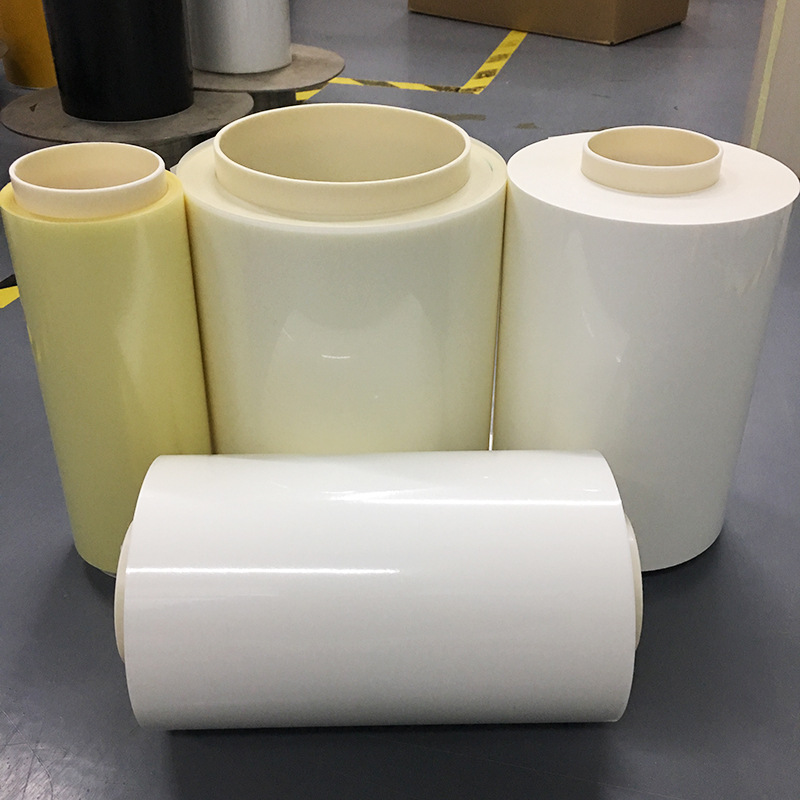

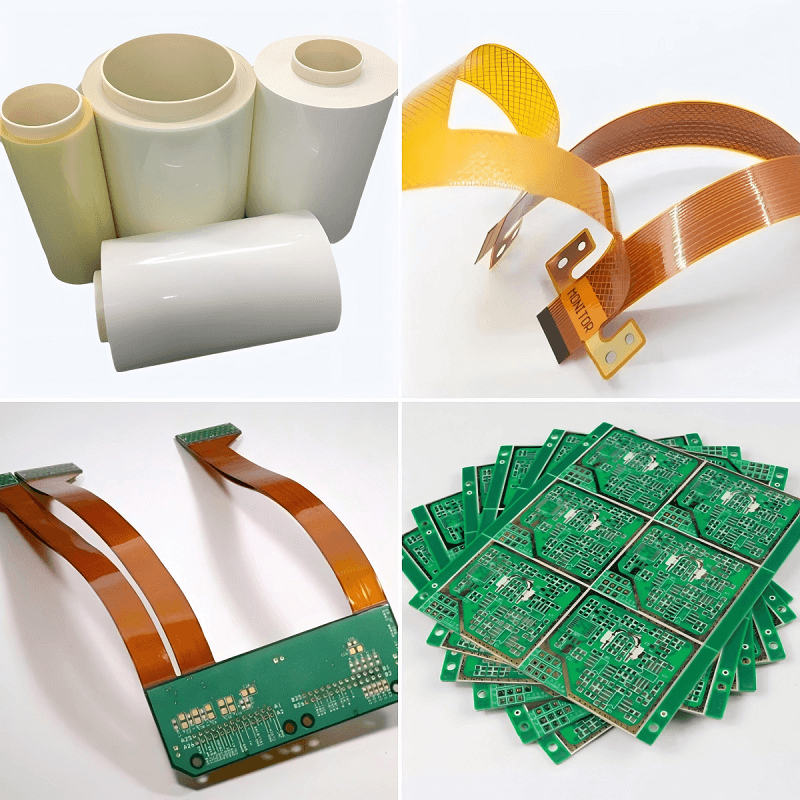

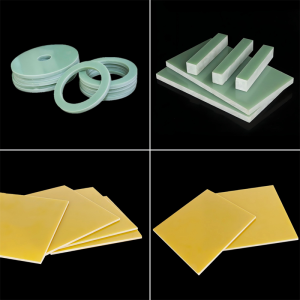

White/Yellow/Transparent |

| Thickness (μm) |

25±3 |

| Peel Strength (N/mm) |

≥1.0 |

| Resin Flow (mm) |

≤0.2 |

| Soldering resistance (260℃±5℃, 10s) |

Qualified |

| Dielectric Constant |

≤3.6 |

| Dielectric Dissipation Factor |

≤0.03 |

Application:

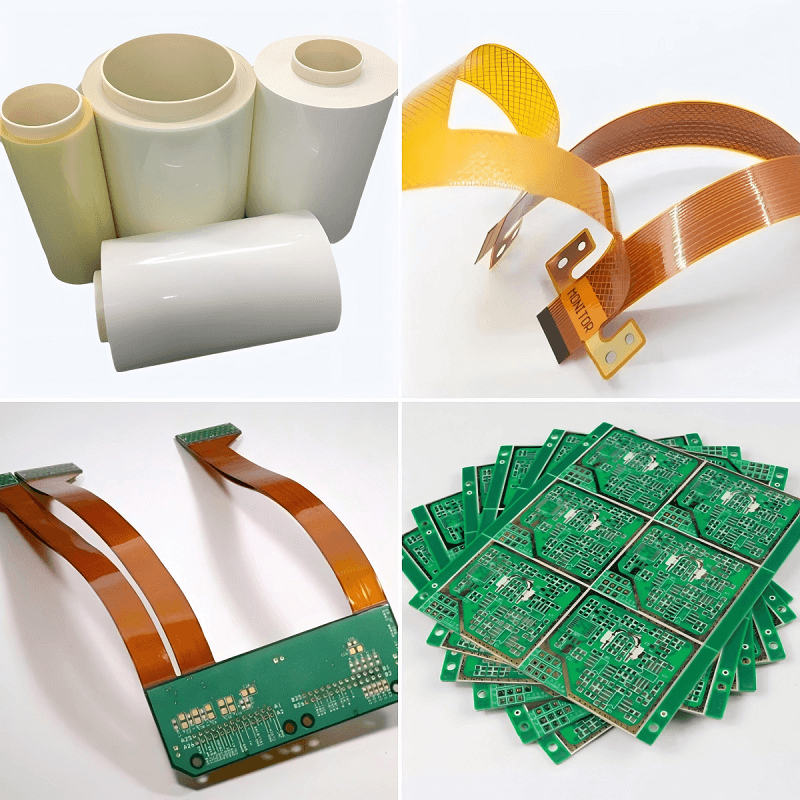

* Flexible Circuit Bonding: Used in bonding flexible printed circuits (FPC) to enhance durability and connectivity.

* Rigid-Flexible PCB Assembly: Joins flexible and rigid circuit layers in multilayer PCB manufacturing.

* Heat-Resistant Adhesion: Bonds materials requiring high-temperature performance, such as polyimide (PI) films and FR4 substrates.

* Metal and Composite Bonding: Provides reliable adhesion between metal plates (like aluminum) and various substrates in electronic devices.

* Strengthening and Reinforcement: Improves mechanical strength in laminated components, particularly in electronics.

* Insulation and Layer Protection: Used for bonding and insulating layers within electronic assemblies to protect against heat and wear.